- Visibility 492 Views

- Downloads 40 Downloads

- Permissions

- DOI 10.18231/j.jdp.2024.029

-

CrossMark

- Citation

Effect of different sintering cycles on the flexural strength and translucency of CAD-CAM milled monolithic zirconia with different thicknesses

Abstract

Context: Zirconia is the preferred material for posterior teeth subjected to high occlusal forces & its fabrication involves the use of CAD/CAM technology. Sintering conditions play a crucial role in determining the grain size, final product stabilization, and mechanical properties of the material. Limited studies are available to determine effect of sintering cycles on mechanical and optical properties of zirconia.

Aims: To investigate flexural strength and translucency produced by two different sintering cycles (conventional and high-speed sintering) on three different thicknesses of CAD-CAM milled monolithic zirconia crowns.

Settings and Design: In vitro study.

Materials and Methods: Zirconia blanks (Dentsply Sirona, Cercon ht diameter 98mm x 12 mm height, Germany) were used to fabricate 30 premolar crowns (N = 30, divided into 2 groups of 15 each) which were constructed in three different occlusal thicknesses (1.5, 2.0, 2.5 mm) using two different sintering cycles: conventional sintering (at 1,450°C for 9 hours 50 minutes) and high-speed sintering (at 1,550°C for 2 hours 55 minutes). Flexural strength and translucency parameter (TP) tested after all crowns were underwent 5,000 times thermocycling test (between 5°C and 55°C).

Statistical analysis used: Intergroup comparison done using unpaired ‘t’ test. Intra-group comparison done using Tukey’s post hoc test.

Results: The effect of sintering procedure on TP was not statistically significant but effect of thickness on TP was statistically significant. As thickness was reduced from 2.5 to 1.5 mm, translucency was increased but flexural strength was decreased. Sintering monolithic zirconia using conventional sintering cycle rendered high flexural strength than high speed sintering cycle but both groups showed higher values than optimum value of flexural strength of zirconia.

Conclusion: The flexural strength increased with the increase of thickness of zirconia crown whereas translucency decreases. Significant differences among flexural strength were also determined between the same thicknesses of the zirconia materials at different sintering programs (p<0.05).

Introduction

All-ceramic restorations are gaining popularity in the field of dentistry, particularly glass ceramics like zirconium, which exhibit excellent aesthetic outcomes in fixed restorations. Zirconia (zirconium dioxide, ZrO2) is the preferred material for posterior teeth subjected to high occlusal forces, and its fabrication involves the use of Computer aided designing/ computer aided manufacturing (CAD/CAM) technology. The process includes scanning, designing, milling, sintering, and glazing of zirconia blanks.[1]

Sintering conditions play a crucial role in determining the grain size, final product stabilization, and mechanical properties of the material. As the firing temperature increases, the grain size tends to enlarge. However, this relationship holds true only up to sintering temperature of 1600°C, beyond which the flexural capacity begins to degrade.[2], [3] Additionally, sintering parameters have been found to influence not only the mechanical properties but also the optical properties such as translucency of zirconia.

Zirconia exhibits susceptibility to aging-related colour changes, and exposure to water, bodily fluids within the mouth, and substances like coffee and tea can lead to discoloration of zirconia restorations.[4] In response to the conventional sintering process, which is time-consuming (taking 4-12 hours) and entails high costs and emotional commitment, the high-speed sintering process has been introduced as an effective alternative. High-speed sintering operates at a temperature of 1580°C and requires only 30 minutes, while speed sintering, at 1510°C, necessitates 30–120 minutes. Previous research suggests that high-speed sintering can produce equal or greater strength than conventional sintering.

Fracture toughness and flexural resistance are essential mechanical properties, with fracture load being a critical consideration.[5] Zirconia has demonstrated excellent performance in these aspects. The thickness of the material layer significantly influences flexural strength, and for zirconium crowns in the occlusal region, a minimal thickness of 1 mm-1.5 mm is typically required. Zirconium materials are relatively new to the industry, and the exploration of innovative manufacturing methods, such as high-speed sintering, may offer valuable insights into their potential applications. [6]

This study was conducted to investigate the flexural strength and translucency of CAD/CAM milled monolithic zirconia crowns produced using two different sintering procedures (high-speed and conventional) across various thicknesses.

The null hypotheses tested were:

There is NO significant difference in flexural strength of CAD/CAM milled monolithic zirconia crowns produced by two different sintering cycles with different thicknesses.

There is NO significant difference in translucency of CAD/CAM milled

Monolithic zirconia crowns produced by two different sintering cycles with different thicknesses.

Materials and Methods

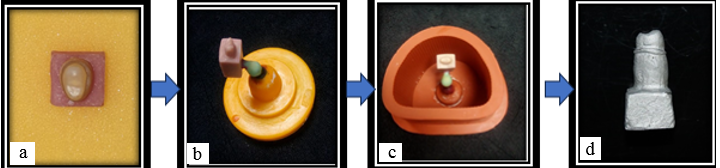

Fabrication procedure of master metal die with base:

30 Extracted premolar teeth were prepared for zirconia crowns with occlusal clearance of 2 mm, axial reduction 1.5 mm with deep chamfer margin and were secured in acrylic block.

Wax pattern for metal die was fabricated and sprued and invested in phosphate bonded investment material and conventional casting with lost wax technique was used to fabricate the Co-Cr metal dies of prepared teeth. ([Figure 1])

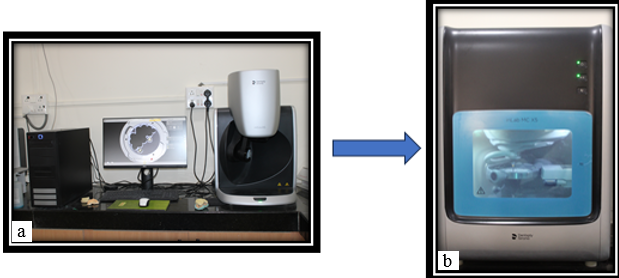

Crown fabrication

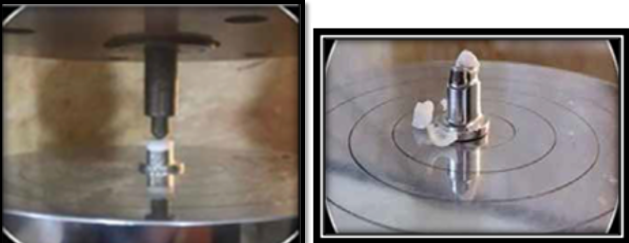

Metal die was scanned with extraoral scanner (Dentsply Sirona) and designing was done in lab SW 19 software. (Dentsply Sirona) specimens were milled in a 5-axis milling machine (In lab MC X5).([Figure 2])

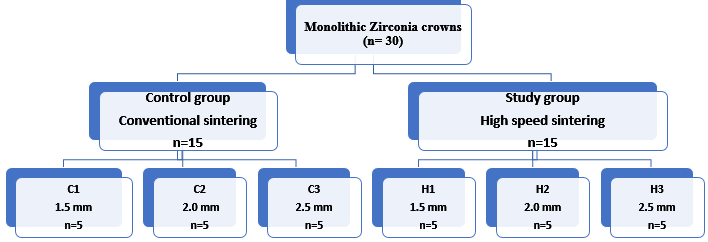

Monolithic Zirconia crowns were then divided into 2 groups according to two sintering methods:

Control group - Conventional sintering.

Study group -High speed sintering.

These were further divided into 3 subgroups of varying thicknesses.

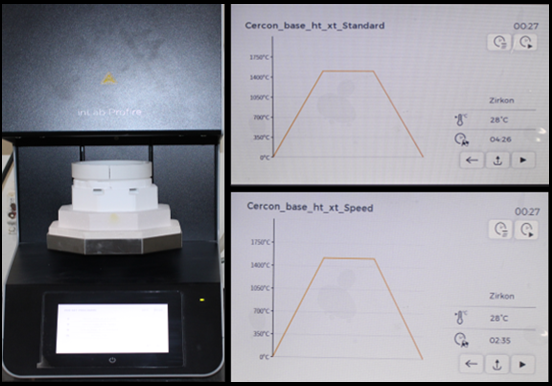

Sintering process

The crowns were placed on the firing stand directly in such a way that the inner surface of the crowns faced downward.

The sintering was programmed according to the instructions of In lab Profire Sintering Unit ([Table 1]) ([Figure 4])

|

Sintering process |

Conventional Sintering |

High speed sintering |

|

Temperature |

1450 Degree Celsius |

1550 Degree Celsius |

|

Holding time |

120mins |

25mins |

|

Time required |

9hrs 50mins |

2hrs 55 minutes |

Thermocycling test

All crowns were mechanically loaded and cycled 5,000 times between two water baths, 5°C and 55°C (Thermocycling system, DORSA).

Each loop took 60 seconds in each bath and 10 seconds to switch between baths.

Translucency Parameter (TP) test

The colour of the specimens was measured using the same spectrophotometer against white (CIE L* = 88.81, a* = −4.98, b* = 6.09) and black (CIE L* = 7.61, a* = 0.45, b* = 2.42) backgrounds relative to the CIE (International Commission on Illumination) standard illuminant D65.

The translucency parameter (TP) values were obtained by calculating the difference in the colour of the specimens against black and white backgrounds using the following formula:

TP = [(L*b − L*w)2 + (a*b − a*w)2 + (b*b − b*w)2] ½

where:

TP – translucency parameter;

L* – degree of lightness;

a* – colour coordinate on the red/green axis;

b* – colour coordinate on the yellow/blue axis;

the subscripts b and w refer to the colour coordinates against black and white backgrounds, respectively.

Flexural strength test

The universal testing machine (Instron 1195, Germany) was used to measure the flexural strength of specimens treated with thermocycling.

A 6 mm diameter testing stamp (chrome-nickel steel; Deutsche, Witten, Germany) was utilized with a 1 mm/min cross head speed ([Figure 5]).

To prevent force peaks, each crown had the stamp placed on the occlusal surface and a 0.1 mm tin foil (Dentaurum, Germany) was placed between the stamp and the crown.

|

Conventional sintering |

Strenth in MPA |

Translucency |

High speed sintering |

Strenth in MPA |

Translucency |

|

C1 |

1152.45 |

16.75 |

H1 |

1059.47 |

15.90 |

|

|

1150.15 |

16.78 |

|

1059.35 |

15.93 |

|

|

1149.30 |

16.80 |

|

1062.25 |

15.91 |

|

|

1152.25 |

16.81 |

|

1060.10 |

15.94 |

|

|

1152.00 |

16.82 |

|

1061.36 |

16.02 |

|

C2 |

1160.12 |

14.75 |

H2 |

1065.12 |

15.11 |

|

|

1159.70 |

14.72 |

|

1066.22 |

15.09 |

|

|

1164.39 |

14.70 |

|

1066.81 |

14.90 |

|

|

1166.68 |

13.95 |

|

1067.34 |

15.06 |

|

|

1163.54 |

14.35 |

|

1068.51 |

15.10 |

|

C3 |

1268.31 |

13.21 |

H3 |

1074.12 |

13.12 |

|

|

1264.20 |

13.32 |

|

1074.74 |

13.14 |

|

|

1271.00 |

13.25 |

|

1075.15 |

13.10 |

|

|

1259.17 |

13.19 |

|

1076.21 |

13.17 |

|

|

1261.04 |

13.18 |

|

1076.35 |

13.20 |

|

C= conventional sintering cycle |

H= high speed sintering cycle |

Statistical analysis

Statistical analysis done using SPSS software.

Unpaired t test followed by Tukey’s post hoc test was used to find pairwise comparison

Results

Following results can be drawn from this study:

The effect of sintering procedure on TP was not statistically significant.

Effect of thickness of monolithic zirconia on TP was statistically significant.

As thickness was reduced from 2.5 to 1.5 mm, translucency was increased

Sintering monolithic zirconia using conventional sintering cycle have high flexural strength than high speed sintering.

Both sintering cycles have comparable results for flexural strength.

|

|

Flexural strength |

Translucency |

||

|

|

Conventional Sintering Mean (SD) |

High Speed Sintering Mean (SD) |

Conventional Sintering Mean (SD) |

High Speed Sintering Mean (SD) |

|

C1 (1.5 mm thickness) |

1151.2 (1.41) |

1060.5 (1.25) |

16.79 (0.27) |

15.94 (0.047) |

|

C2 (2 mm thickness) |

1162.9 (2.95) |

1066.8 (1.26) |

14.49 (0.34) |

15.05 (0.08) |

|

C3 (2.5 mm thickness) |

1264.7 (4.92) |

1075.3 (0.95) |

13.23 (0.05) |

13.14 (0.03) |

|

One-way Anova F test value |

F = 1673.0 |

F = 202.33 |

F = 397.852 |

F = 2682.0 |

|

p value (overall) |

p< 0.001** |

p< 0.001** |

p< 0.001** |

p< 0.001** |

|

C1 vs C2^ |

p< 0.001** |

p< 0.001** |

p< 0.001** |

p< 0.001** |

|

C1vs C3^ |

p< 0.001** |

p< 0.001** |

p< 0.001** |

p< 0.001** |

|

C2 vs C3^ |

p< 0.001** |

p< 0.001** |

p< 0.001** |

p< 0.001** |

|

|

Conventional Sintering Mean (SD) |

High Speed Sintering Mean (SD) |

Unpaired t test |

P value, Significance |

|

|

Flexural strength |

|||

|

C1 (1.5 mm thickness) |

1151.2 (1.41) |

1060.5 (1.25) |

t = 107.074 |

p< 0.001** |

|

C2 (2 mm thickness) |

1162.9 (2.95) |

1066.8 (1.26) |

t = 66.89 |

p< 0.001** |

|

C3 (2.5 mm thickness) |

1264.7 (4.92) |

1075.3 (0.95) |

t = 84.4 |

p< 0.001** |

|

|

Translucency |

|||

|

C1 (1.5 mm thickness) |

16.79 (0.27) |

15.94 (0.047) |

t = 34.6 |

P< 0.001** |

|

C2 (2 mm thickness) |

14.49 (0.34) |

15.05 (0.08) |

t = -3.50 |

p =0.008* |

|

C3 (2.5 mm thickness) |

13.23 (0.05) |

13.14 (0.03) |

t = 2.703 |

P =0.027* |

Discussion

The study revealed significant variations in flexural strength concerning different sintering cycles and thicknesses, leading to the rejection of the first null hypothesis. Notably, sintering monolithic zirconia at higher temperatures and prolonging the sintered-holding time resulted in increased flexural strength compared to lower sintering temperatures and shorter holding times. This observed enhancement in flexural strength is likely associated with the maturation of crystal structures, reduction in number of defects on grain boundaries, and the growth of grain sizes, achieved through the elevation of sintering temperature or prolonged holding time. These findings align with supporting evidence from other studies. [7], [8], [9]

Currently, the final sintering temperature of zirconia ceramics available for dental application varies between 1,350 and 1,550C depending on the manufacturers.[10], [11] The influence of increasing sintering temperature and prolonging the sintered process extends to the properties of monolithic zirconia, affecting both its microstructure and crystalline phases. The sintering process aids in eliminating inter-particle pores within the granular material by promoting atomic diffusion driven by capillary forces. As the sintering temperature rises or the sintering time is prolonged, zirconia particles exhibit a higher capability to join together, minimizing pores on grain boundaries through solid-state diffusion. This results in increased material density, ultimately enhancing the strength of zirconia. Consequently, groups subjected to longer holding times and higher sintering temperatures achieved higher flexural strength than those under regular sintering programs, consistent with findings from other studies. [7], [9], [2], [12]

Regarding translucency, the study demonstrated significant changes with different thicknesses but not with different sintering cycles, leading to the rejection of the second null hypothesis. The grain size, influenced by sintering conditions, plays a crucial role in final product stabilization and mechanical properties. With higher firing temperatures, the grain size tends to increase. Previous research by Kim et al suggested an inverse relationship between the thickness of monolithic zirconia and lightness.

Also, Sato and Shimada[13] found that the rate of tetragonal to monoclinic transformation slightly increased with increasing grain-size in the sintered zirconia. Ersoy et al found that zirconia samples exhibited the highest flexural strength when sintering was carried out at 1580°C for 10 minutes, with all experimented sintering parameters providing full sinterization for green zirconia.[2] Zhang et al proposed an optimum sintering temperature of 1100°C, explaining that lower temperatures result in low densification, leading to significant light scattering and opaque samples, while higher temperatures produce additional absorption and scattering defects. [12]

Juntavee & Attashu's study indicated that modifying the sintering parameters of monolithic zirconia significantly affects strength. Lower sintering temperatures may decrease flexural strength, resulting in a brittle restoration, while higher sintering temperatures increase grain size, improving mechanical characteristics and strength. [14]

Nowadays many studies[15], [16] have introduced translucency to zirconia by consolidating nano powders to full density with nanocrystals through the industrial sintering technique such as hot-isostatic pressing (HIP), microwave and millimetres wave sintering, spark plasma sintering (SPS). Those zirconia products have been widely used in the industrial field. Meanwhile the fabrication of zirconia dental ceramic could learn from those methods. In addition, the mechanical and physical properties of zirconia core are required to be consistent with translucency for clinical application.

To summarize this study underscores the intricate relationship between sintering conditions, microstructure, mechanical & optical properties in monolithic zirconia crowns. The findings offer valuable insights for optimizing the fabrication process and enhancing the performance of zirconia restorations in dental applications.

Conclusion

Time-saving and cost-effective technologies have shown comparable results

The flexural strength increased with the increase of thickness of zirconia crown

Significant differences also determined between the same thicknesses of the zirconia materials at different sintering programs (p<0.05).

Clinical Implications

The flexural strength of monolithic zirconia increases as the thickness and sintering temperature increases.

Monolithic zirconia crown of optimum occlusal thickness sintered at high sintering temperature for longer duration are recommended for higher strength & optimal translucency.

Source of Funding

None.

Conflict of Interest

None.

References

- Mahmoud S, Kanaan S. Influence of sintering technique on fracture load of monolithic zirconia with different thicknesses. J Osseointegration. 2022;14(1):31-7. [Google Scholar]

- Ersoy N, Aydogdu H, Degirmenci B, Cokuk N, Sevimay M. The effects of sintering temperature and duration on the flexural strength and grain size of zirconia. Acta Biomater Odontol Scand. 2015;1(2-4):43-50. [Google Scholar]

- Jansen J, Lümkemann N, Letz I, Pfefferle R, Sener B, Stawarczyk B. Impact of high-speed sintering on translucency, phase content, grain sizes, and flexural strength of 3Y-TZP and 4Y-TZP zirconia materials. J Prosthet Dent. 2019;122(4):396-403. [Google Scholar]

- Nida M, Nikita V, Kishor M, Smita A, Ulhas T, Vilas R. Color Stability of Lithium Disilicate and Monolithic Zirconia in Various Staining Liquids: An Invitro Study. J Chem Health Risks. 2024;14(1):2389-95. [Google Scholar]

- Stawarczyk B, Ozcan M, Hallmann L, Ender A, Mehl A, Hammerlet C. The effect of zirconia sintering temperature on flexural strength, grain size, and contrast ratio. Clin Oral Investing. 2013;17(1):269-74. [Google Scholar]

- Wiedenmann F, Pfefferle R, Reichert A, Jerman E, Stawarczyk B. Impact of high-speed sintering, layer thickness and artificial aging on the fracture load and two-body wear of zirconia crowns. Dent Mater. 2020;36(7):846-53. [Google Scholar]

- Stawarczyk B, Özcan M, Hallmann L, Ender A, Mehl A, Hammerlet C. The effect of zirconia sintering temperature on flexural strength, grain size, and contrast ratio. Clin Oral Investig. 2013;17(1):269-74. [Google Scholar]

- Jiang L, Liao Y, Wan Q, Li W. Effects of sintering temperature and particle size on the translucency of zirconium dioxide dental ceramic. J Mater Sci Mater Med. 2011;22(11):2429-35. [Google Scholar]

- Hjerppe J, Vallittu P, Froberg K, Lassila L. Effect of sintering time on biaxial strength of zirconium dioxide. Dent Mater. 2009;25(2):166-71. [Google Scholar]

- Denry I, Kelly J. State of the art of zirconia for dental applications. Dent Mater. 2008;24(3):299-307. [Google Scholar]

- Lazar D, Bottino M, Ozcan M, Valandra L, Amaral R, Usui V. Y-TZP ceramic processing from coprecipitated powders: a comparative study with three commercial dental ceramics. Dent Mater. 2008;24(12):1676-85. [Google Scholar]

- Zhang H, Kim B, Morita K, ; YH, Yoshio S. Effect of sintering temperature on optical properties and microstructure of translucent zirconia prepared by high-pressure spark plasma sintering. Sci Technol Adv Mater. 2011;12(5). [Google Scholar] [Crossref]

- Sato T, Shimada M. Transformation of yttria-doped tetragonal ZrO2 polycrystals by annealing in water. J Am Ceram Soc. 1985;68(6):356-9. [Google Scholar]

- Juntavee N, Attashu S. Effect of sintering process on colour parameters of nano-sized yttria partially stabilized tetragonal monolithic zirconia. J Clin Exp Dent. 2018;10(8):794-804. [Google Scholar]

- Casolco S, Xu J, Garay J. Transparent/translucent polycrystalline nanostructured yttria stabilized zirconia with varying colors. Scr Mater. 2008;58(6):516-9. [Google Scholar]

- Mazaheri M, Zahedi AM, Haghighatzadeh M, Sadrnezhaad SK. Sintering of titania nanoceramic: densification and grain growth. Ceram Int. 2009;35:685-91. [Google Scholar]

How to Cite This Article

Vancouver

Katkade AS, Mustabshira N, Mahale KM, Khalikar SA, Rajguru VL, Tandale UE, Mahajan SV. Effect of different sintering cycles on the flexural strength and translucency of CAD-CAM milled monolithic zirconia with different thicknesses [Internet]. J Dent Panacea. 2024 [cited 2025 Oct 27];6(3):144-149. Available from: https://doi.org/10.18231/j.jdp.2024.029

APA

Katkade, A. S., Mustabshira, N., Mahale, K. M., Khalikar, S. A., Rajguru, V. L., Tandale, U. E., Mahajan, S. V. (2024). Effect of different sintering cycles on the flexural strength and translucency of CAD-CAM milled monolithic zirconia with different thicknesses. J Dent Panacea, 6(3), 144-149. https://doi.org/10.18231/j.jdp.2024.029

MLA

Katkade, Akanksha Sanjay, Mustabshira, Nida, Mahale, Kishor M, Khalikar, Smita A, Rajguru, Vilas L, Tandale, Ulhas E, Mahajan, Sonali V. "Effect of different sintering cycles on the flexural strength and translucency of CAD-CAM milled monolithic zirconia with different thicknesses." J Dent Panacea, vol. 6, no. 3, 2024, pp. 144-149. https://doi.org/10.18231/j.jdp.2024.029

Chicago

Katkade, A. S., Mustabshira, N., Mahale, K. M., Khalikar, S. A., Rajguru, V. L., Tandale, U. E., Mahajan, S. V.. "Effect of different sintering cycles on the flexural strength and translucency of CAD-CAM milled monolithic zirconia with different thicknesses." J Dent Panacea 6, no. 3 (2024): 144-149. https://doi.org/10.18231/j.jdp.2024.029